Basic Info.

Structure

Vertical

After-Sales Service

Video Support

Transport Package

Wooden Case

Specification

1750*1150*1050mm

Trademark

BF

Origin

Henan, China

HS Code

4016931000

Production Capacity

20000 Set/Year

Product Description

--Brief introduction of Hydraulic Hot Press Rubber Wrist Band Logo Rubber O Ring Moulding Machine

Product features:

The BF-R1 series tablet machine has the characteristics of simple structure, high pressure, high efficiency and wide applicability.

Product description and usage:

BF-R1 series flatbed machine is mainly suitable for vulcanization molding of various common flat rubber molded products. Suitable for the production of various rubber products, silicone products, seals, O-rings, oil seals, auto parts, rubber shock pads, keyboards, medical rubber parts, electrical insulation parts and other rubber products and bakelite products, handicrafts, etc. It can also be used for compression molding of other thermosetting plastics, foam products, foam resins, bakelite, thin metals, building materials and other models.

Three, structural characteristics:

3.1 This machine is guided by four columns, and the main machine table is composed of upper plate (also called upper beam), lower frame, movable plate (moving platform), cylinder group and upright column. The oil cylinder is a plunger structure and is installed in the lower base. Two fast oil cylinders are installed on both sides of the lower base.

3.2. The equipment has an independent power mechanism and electrical system. The electrical box is fastened to the right side of the host. It uses a PLC programmable controller and is equipped with an LCD display. The buttons are centrally controlled and easy to operate. The working pressure and heating temperature can be adjusted within a certain range. This model has two working modes: manual and semi-automatic.

3.3. This machine has a single-machine single-pump station structure, and can also be manufactured with dual or multiple machines according to user needs. The oil pump is located on the right side of the main engine, and the lower frame doubles as an oil tank;

3.4. When the machine is working, the plunger moves from bottom to top to close the mold, press to form, and has the functions of automatic heat preservation, pressure holding and exhaust to ensure product quality.

Four, function introduction:

4.1. With automatic pressure compensation function, in the rubber product compression process, the pressure drop caused by the flow of raw materials can be automatically compensated.

4.2. Automatic exhaust time, exhaust times, secondary exhaust, up and down residence time, heating temperature, vulcanization time, and mold clamping pressure can be set during the exhaust process, which is easy to operate. Vulcanization countdown display function, early warning function for the end of vulcanization, and automatic mold opening.

4.3, Fast opening and closing of the mold, high production efficiency, slow locking and pressure, to protect the mold.

4.4. When the product is vulcanized and formed, the oil pump motor stops working, which saves electricity.

4.5. Using segmented heating tubes, the hot plate has high temperature control accuracy and energy saving.

4.6. Reasonable oil circuit configuration, saving energy consumption, using imported valves, safer and more reliable to use.

4.7. The hydraulic cylinder adopts German imported technology, and the seal adopts Japanese original imported NOK, which is reliable in sealing and long in life.

4.8, The design is reasonable, the operation is simple and easy to understand, and the maintenance is convenient.

4.9, single-layer and multi-layer options are available.

Main technical parameters of the equipment:

Main performance characteristics

1. The oil cylinder adopts advanced sealing structure, reasonable design and reliable performance.

2. With automatic control of mold clamping, manual exhaust, automatic pressure compensation, vulcanization timing, time alarm, manual control

Control down the function.

3. Description of the main components of the host

3.1. Column: The column is made of high-quality 45# steel. After quenching and tempering, the strength and tensile force of the column are improved, and it is not easy to deform and break.

3.2 Plunger: The material of the cylinder is QT500-7, the cylinder diameter is Φ200mm, and the quantity is 1 piece.

3.3. The materials of upper and lower base and platform are all QT500-7.

3.4. Hot plate: The hot plate is made of Q235A high-quality carbon steel, which has been subjected to artificial vibration or high temperature tempering aging treatment, with good surface finish and strong wear resistance.

3.5. Seals: The cylinder seals use YX type polyurethane oil seals, which are resistant to oil, aging and abrasion.

3.6. Heat insulation board: The heat insulation board adopts high-quality calcium silicate board, with a pressure resistance of 3.5Mpa and a heat insulation coefficient of 0.031.

3.7. Electrical system: This electromechanical device adopts the well-known brands of Chint and Delixi. The electrical device has the advantages of small size, compact structure, fatigue resistance, and is suitable for continuous high-strength work.

3.8. Insulating sheets are installed in the front and rear covers of the hot plate of this machine.

Three, payment method: spot supply, delivery can be made when the payment is received, and a full value-added tax invoice will be issued after the full payment.

Fourth, the method of transportation: the seller is responsible for contacting and distributing the goods to the buyer's factory.

Fifth, the service tenet of the equipment for the warranty year.

Service( Efficient arrangement, safe transportation)

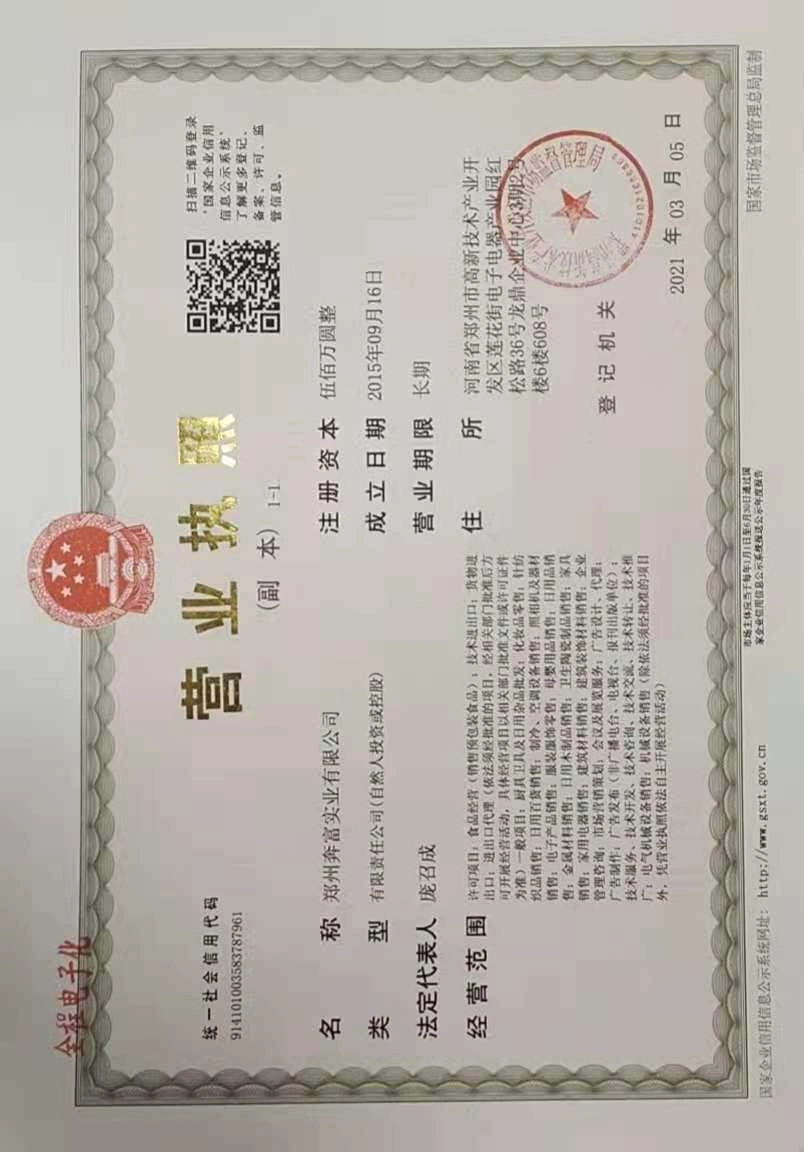

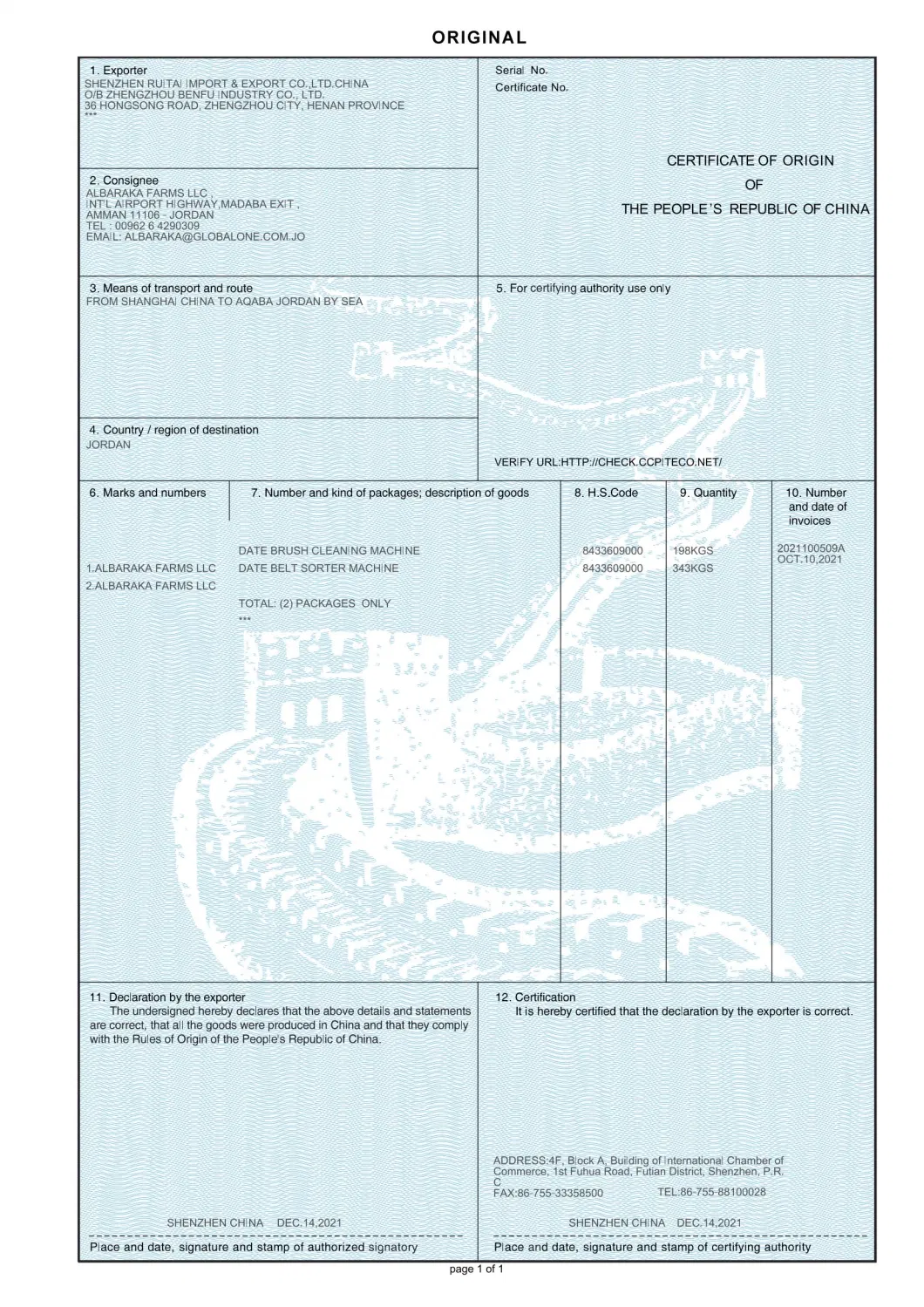

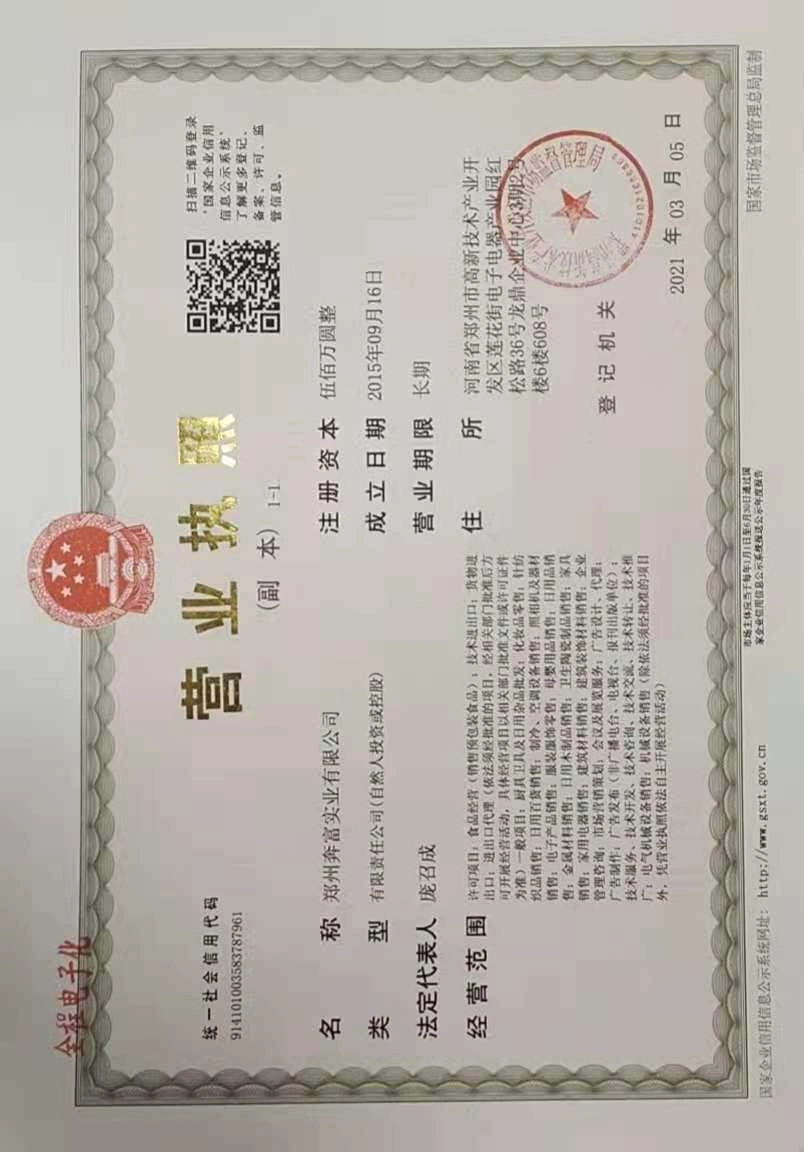

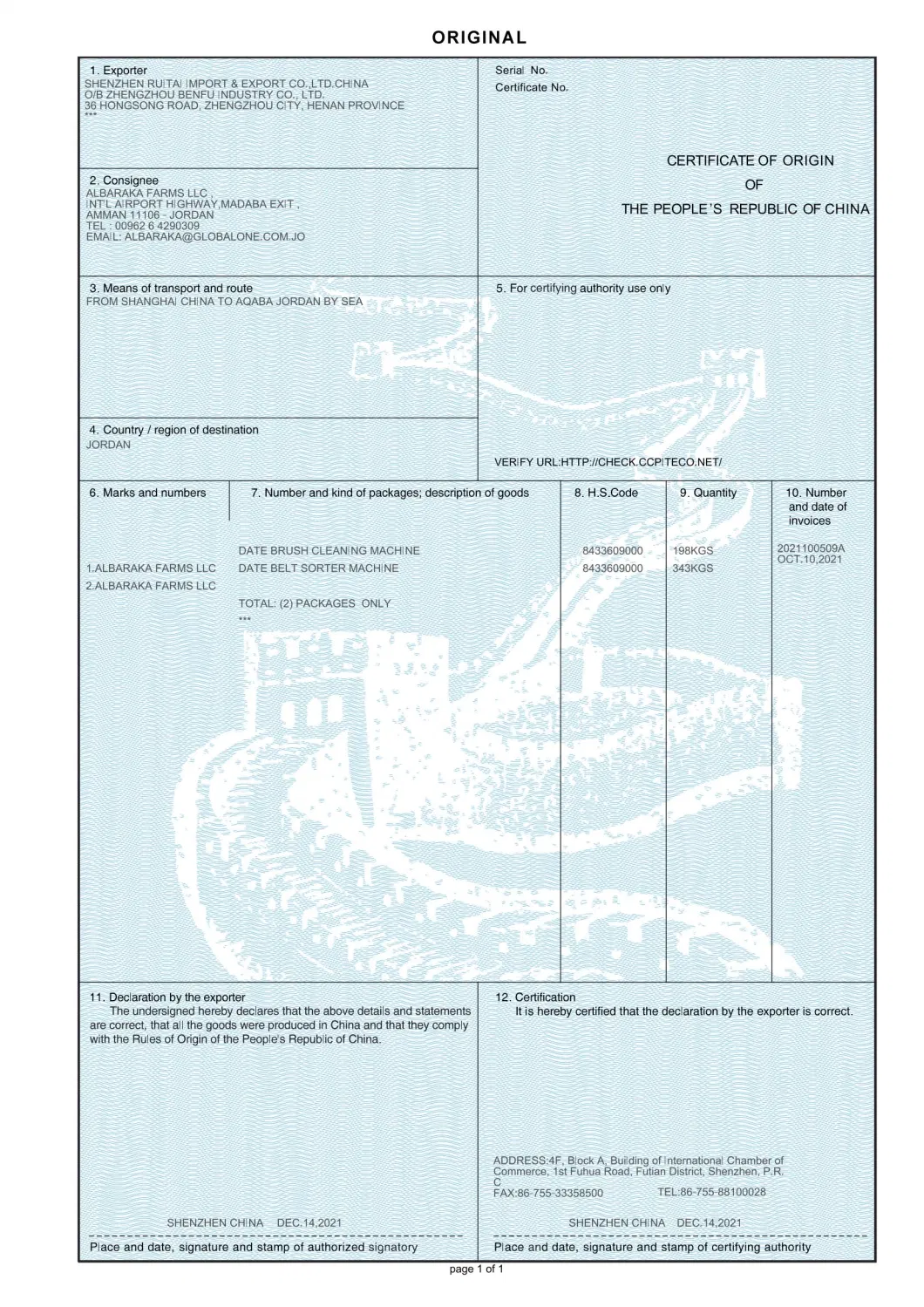

Various certificate guarantees

Various certificate guarantees

Frequently Asked Questions

Q: What's Service commitment?

A: 1.Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Q: What to do if the machine has a problem?

A: 24 hours timely response of mail and phone calls. If the parts broken belong to non-artificial factors within 12 months, we offer free replacement. If beyond 12 months, customers should bear the freight back and forth and accessories cost.

Q: How long is the warranty of your equipment?

A: Our warranty period is one year generally.

Q: What is your payment term?

A: Our usual payment term is: 30% TT in advance, 70% TT before shipment. Other ways can also be received after we both sides discussion and agreement.

Q: Does your price include freight?

A: Our usual price is based on FOB Shanghai, if you request CIF, please give us your delivery port, and we will give you CIF price.

Product features:

The BF-R1 series tablet machine has the characteristics of simple structure, high pressure, high efficiency and wide applicability.

Product description and usage:

BF-R1 series flatbed machine is mainly suitable for vulcanization molding of various common flat rubber molded products. Suitable for the production of various rubber products, silicone products, seals, O-rings, oil seals, auto parts, rubber shock pads, keyboards, medical rubber parts, electrical insulation parts and other rubber products and bakelite products, handicrafts, etc. It can also be used for compression molding of other thermosetting plastics, foam products, foam resins, bakelite, thin metals, building materials and other models.

Three, structural characteristics:

3.1 This machine is guided by four columns, and the main machine table is composed of upper plate (also called upper beam), lower frame, movable plate (moving platform), cylinder group and upright column. The oil cylinder is a plunger structure and is installed in the lower base. Two fast oil cylinders are installed on both sides of the lower base.

3.2. The equipment has an independent power mechanism and electrical system. The electrical box is fastened to the right side of the host. It uses a PLC programmable controller and is equipped with an LCD display. The buttons are centrally controlled and easy to operate. The working pressure and heating temperature can be adjusted within a certain range. This model has two working modes: manual and semi-automatic.

3.3. This machine has a single-machine single-pump station structure, and can also be manufactured with dual or multiple machines according to user needs. The oil pump is located on the right side of the main engine, and the lower frame doubles as an oil tank;

3.4. When the machine is working, the plunger moves from bottom to top to close the mold, press to form, and has the functions of automatic heat preservation, pressure holding and exhaust to ensure product quality.

Four, function introduction:

4.1. With automatic pressure compensation function, in the rubber product compression process, the pressure drop caused by the flow of raw materials can be automatically compensated.

4.2. Automatic exhaust time, exhaust times, secondary exhaust, up and down residence time, heating temperature, vulcanization time, and mold clamping pressure can be set during the exhaust process, which is easy to operate. Vulcanization countdown display function, early warning function for the end of vulcanization, and automatic mold opening.

4.3, Fast opening and closing of the mold, high production efficiency, slow locking and pressure, to protect the mold.

4.4. When the product is vulcanized and formed, the oil pump motor stops working, which saves electricity.

4.5. Using segmented heating tubes, the hot plate has high temperature control accuracy and energy saving.

4.6. Reasonable oil circuit configuration, saving energy consumption, using imported valves, safer and more reliable to use.

4.7. The hydraulic cylinder adopts German imported technology, and the seal adopts Japanese original imported NOK, which is reliable in sealing and long in life.

4.8, The design is reasonable, the operation is simple and easy to understand, and the maintenance is convenient.

4.9, single-layer and multi-layer options are available.

Main technical parameters of the equipment:

| PNominal clamping force | 0.50MN 50t |

| Flat plate (hot plate) specification 400x400x thickness 60mm Material | Q235 high quality carbon structure steel |

| Number of working layers | 1 layer |

| Number of hot plates | 2 pieces |

| Hot plate spacing | 250mm |

| Parallelism of hot plate | ≤0,09mm |

| The surface roughness of the hot plate | Ra≤2.5 μm |

| Heating method | Electric heating |

| The heating power of each heating plate | is 500w*6=3kw |

| Heating temperature | 200°C |

| Temperature control method | Temperature control meter |

| Motor power | 2.2KW |

| Pressure per square centimeter | 32kg/cm2 |

| Plunger stroke/diameter | 250mm /∮200mm |

| Material | QT500-7 |

| Number of cylinders | 1 set Material: QT500-7 |

| Use system pressure | 16Mpa |

| Structure | four-post type |

| Number of columns/diameter 4 pieces / ∮50mm | 45# steel |

| Control mode | manual control manual control valve |

| Weight | about 1300Kg |

Main performance characteristics

1. The oil cylinder adopts advanced sealing structure, reasonable design and reliable performance.

2. With automatic control of mold clamping, manual exhaust, automatic pressure compensation, vulcanization timing, time alarm, manual control

Control down the function.

3. Description of the main components of the host

3.1. Column: The column is made of high-quality 45# steel. After quenching and tempering, the strength and tensile force of the column are improved, and it is not easy to deform and break.

3.2 Plunger: The material of the cylinder is QT500-7, the cylinder diameter is Φ200mm, and the quantity is 1 piece.

3.3. The materials of upper and lower base and platform are all QT500-7.

3.4. Hot plate: The hot plate is made of Q235A high-quality carbon steel, which has been subjected to artificial vibration or high temperature tempering aging treatment, with good surface finish and strong wear resistance.

3.5. Seals: The cylinder seals use YX type polyurethane oil seals, which are resistant to oil, aging and abrasion.

3.6. Heat insulation board: The heat insulation board adopts high-quality calcium silicate board, with a pressure resistance of 3.5Mpa and a heat insulation coefficient of 0.031.

3.7. Electrical system: This electromechanical device adopts the well-known brands of Chint and Delixi. The electrical device has the advantages of small size, compact structure, fatigue resistance, and is suitable for continuous high-strength work.

3.8. Insulating sheets are installed in the front and rear covers of the hot plate of this machine.

Three, payment method: spot supply, delivery can be made when the payment is received, and a full value-added tax invoice will be issued after the full payment.

Fourth, the method of transportation: the seller is responsible for contacting and distributing the goods to the buyer's factory.

Fifth, the service tenet of the equipment for the warranty year.

Service( Efficient arrangement, safe transportation)

Frequently Asked Questions

Q: What's Service commitment?

A: 1.Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Q: What to do if the machine has a problem?

A: 24 hours timely response of mail and phone calls. If the parts broken belong to non-artificial factors within 12 months, we offer free replacement. If beyond 12 months, customers should bear the freight back and forth and accessories cost.

Q: How long is the warranty of your equipment?

A: Our warranty period is one year generally.

Q: What is your payment term?

A: Our usual payment term is: 30% TT in advance, 70% TT before shipment. Other ways can also be received after we both sides discussion and agreement.

Q: Does your price include freight?

A: Our usual price is based on FOB Shanghai, if you request CIF, please give us your delivery port, and we will give you CIF price.